В современном сельском хозяйстве и садоводстве мы сталкиваемся с общей проблемой: что делать с постоянно растущими органическими отходами — растительными остатками, навозом, обрезками веток, пищевыми отходами… Захоронение занимает место, сжигание загрязняет среду, а складирование приводит к болезням.

Но если посмотреть под другим углом, эти так называемые «отходы» на самом деле являются недооцененным «золотым месторождением». Они содержат столь необходимые почве органические вещества и питательные элементы, будучи ценным сырьем для производства высококлассных органических удобрений. Ключевой вопрос: как эффективно, чисто и в масштабах осуществить эту трансформацию «мусора в золото»?

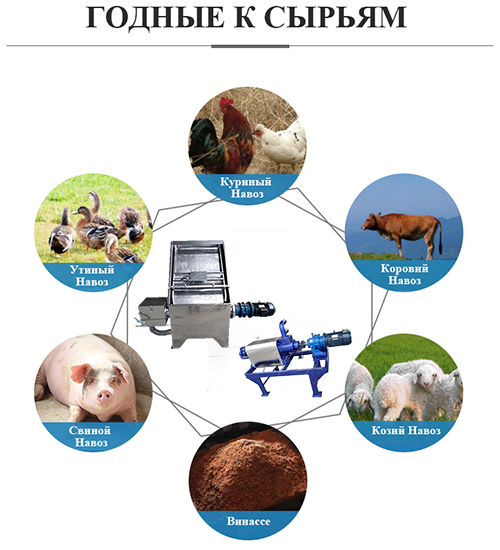

Organic Fertilizer Raw Materials

Ответ кроется в профессиональном промышленном компостере.

Болевые точки традиционного компостирования: зачем вам нужен технологический апгрейд?

Традиционное открытое компостирование — процесс долгий (от 3-6 месяцев и более), сильно зависящий от погоды, с неравномерным брожением, часто сопровождаемый запахами, фильтратом и насекомыми. Это не только неэффективно, но и может создать проблемы с соблюдением экологических норм.

Для крупных животноводческих комплексов, больших ферм, ландшафтных компаний или производителей органических удобрений традиционные методы уже не отвечают потребностям в снижении затрат, повышении эффективности и «зеленом» развитии.

Наше решение: эффективная, интеллектуальная, комплексная система компостирования

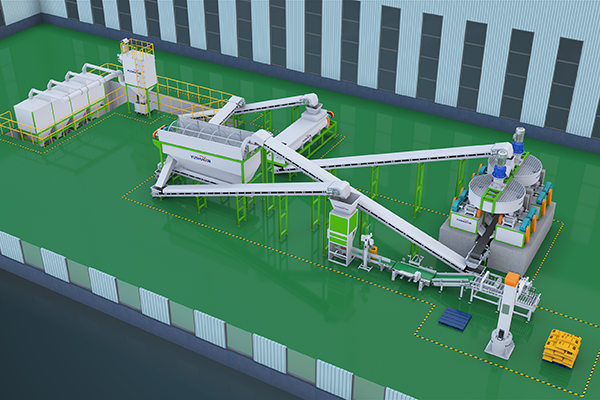

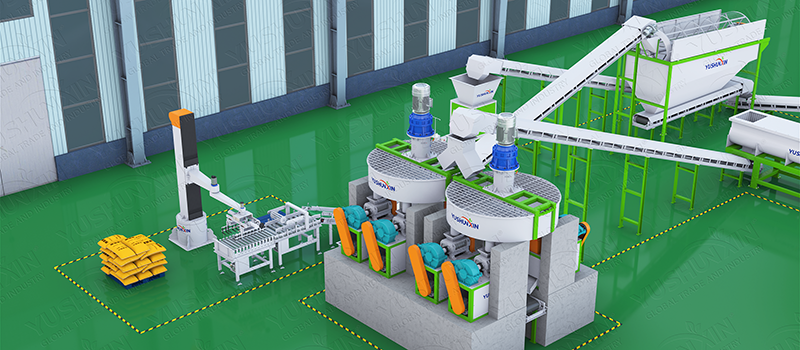

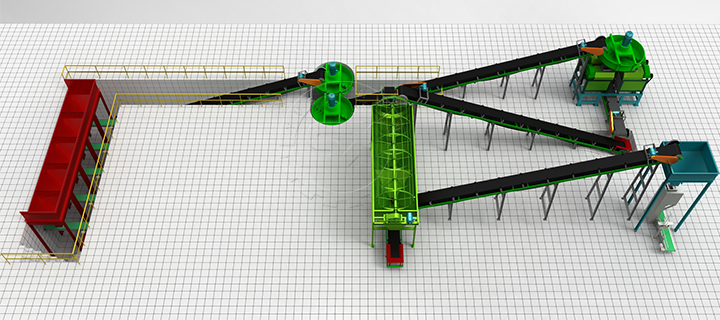

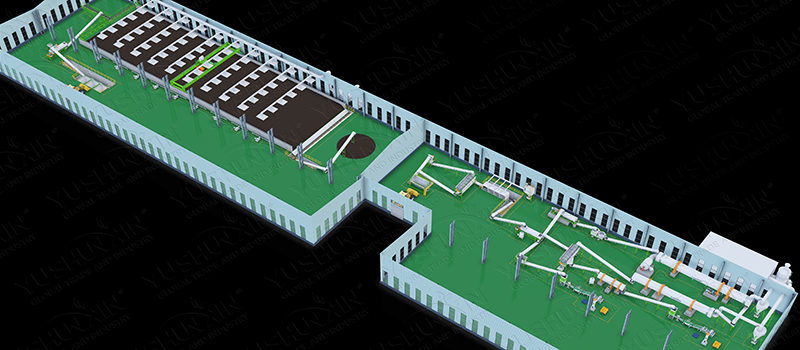

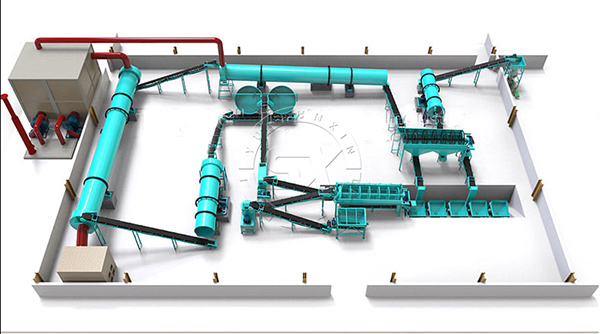

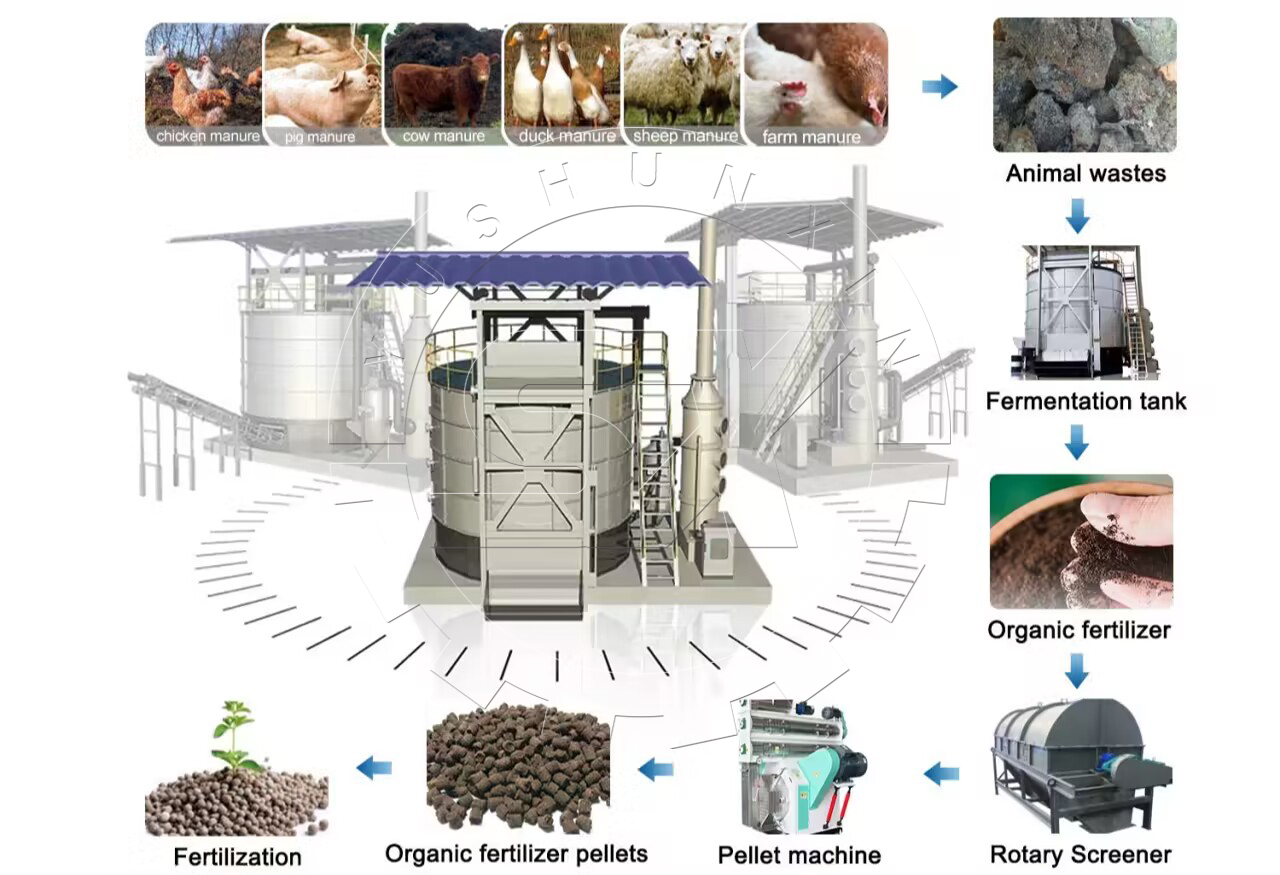

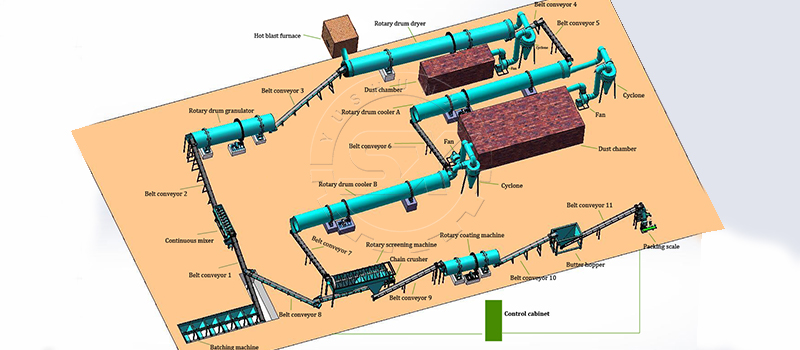

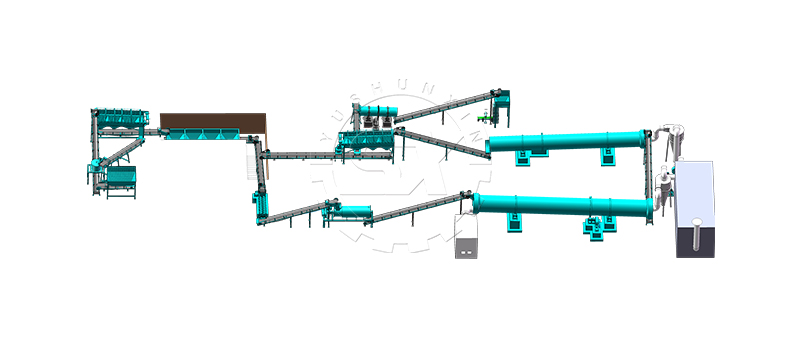

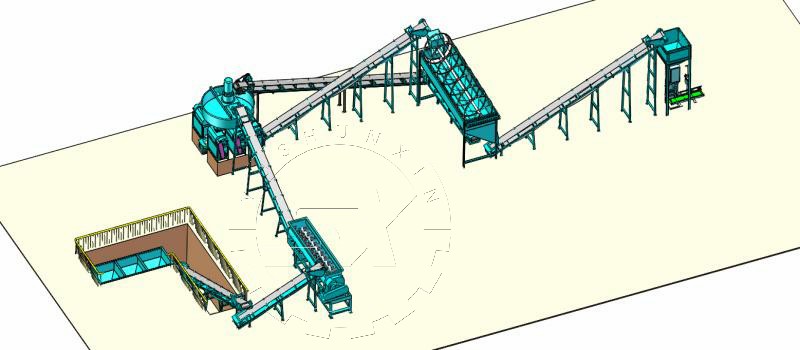

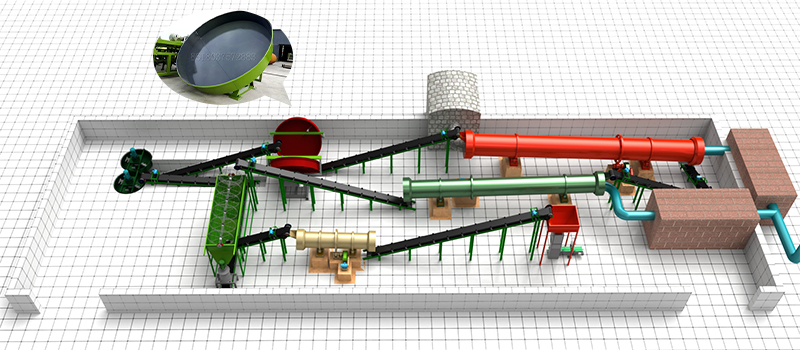

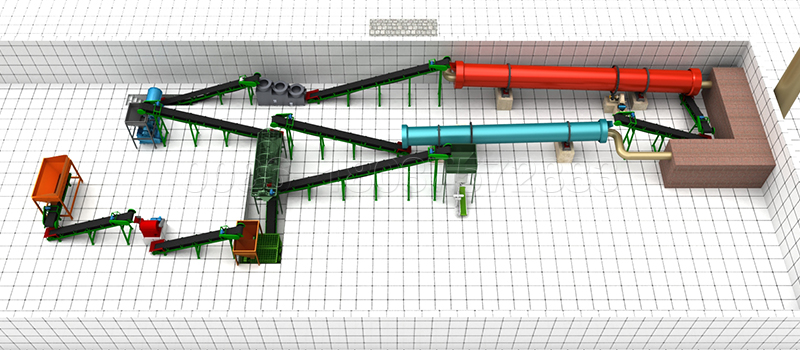

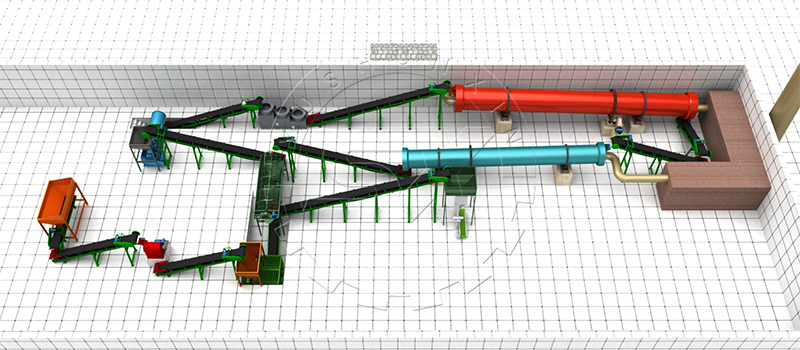

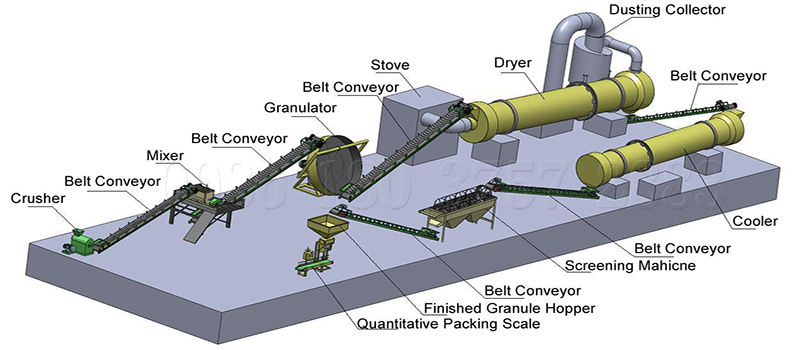

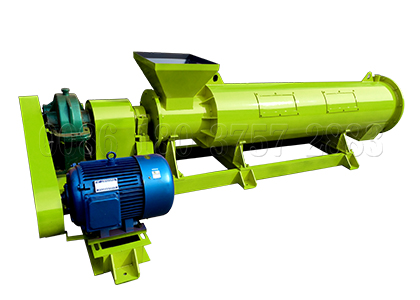

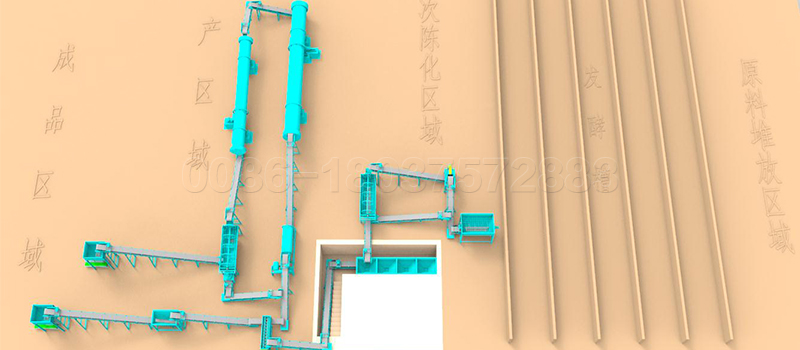

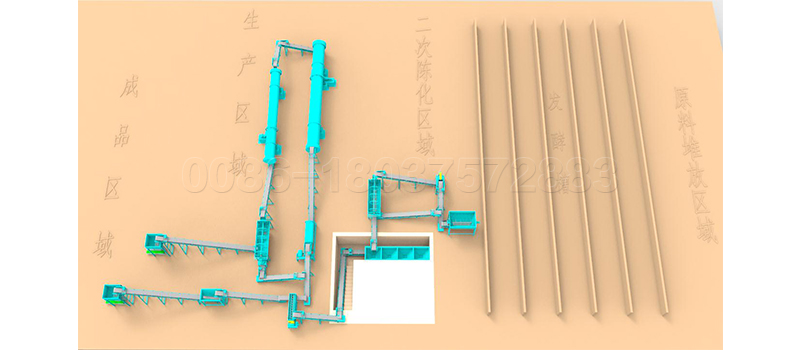

Мы предлагаем не просто машину, а полное решение для быстрого преобразования органических отходов в высококачественное органическое удобрение. Наш компостер разработан для непрерывного, высокоэффективного коммерческого производства.

Biofertilizer composting machine

Ключевые преимущества, создающие реальную ценность для вас:

1. Крайне короткий цикл ферментации

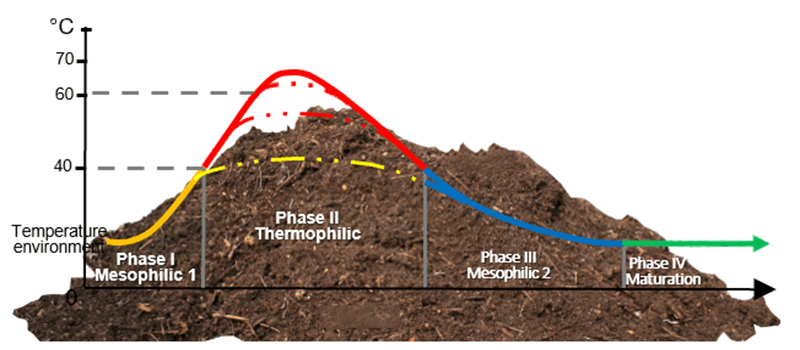

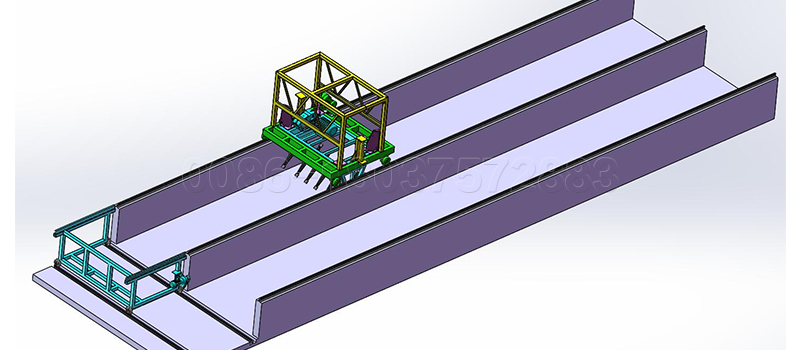

С месяцев до дней: Благодаря системе точного контроля аэрации, перемешивания и температуры, создающей оптимальную среду для микроорганизмов, процесс ферментации сокращается с нескольких месяцев до 7-15 дней, значительно повышая эффективность производства и оборачиваемость средств.

2. Экологичность и чистое производство

Контроль запахов: Встроенные системы биофильтрации или орошения эффективно нейтрализуют неприятные запахи (аммиак, сероводород), возникающие в процессе, обеспечивая дружелюбность к окружающей среде предприятия.

Без вторичного загрязнения: Герметичная или полузакрытая конструкция предотвращает утечку фильтрата, который можно собирать и возвращать в процесс ферментации, достигая нулевого сброса сточных вод.

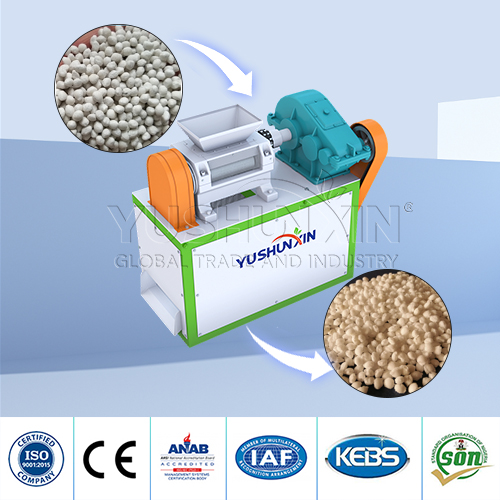

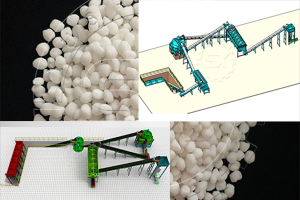

3. Более высокая эффективность удобрения, стабильное качество

Равномерная и полная ферментация: Уникальная система перемешивания гарантирует, что каждая часть материала получает одинаковое количество кислорода, тепла и влаги. Процесс завершен полностью, уничтожаются семена сорняков, патогены и личинки вредителей. Получаемое удобрение имеет высокую степень зрелости, стабильные характеристики и безопасно.

Сохранение питательных веществ: Интеллектуальный контроль температуры предотвращает значительные потери азота из-за длительного перегрева, сохраняя больше доступных питательных веществ.

4. Экономия времени и труда, интеллектуальное управление

Автоматическая работа: Возможность оснащения интеллектуальной системой управления (PLC) позволяет задавать параметры одной кнопкой, автоматизируя процессы перемешивания, аэрации и контроля температуры, что значительно снижает зависимость от ручного труда.

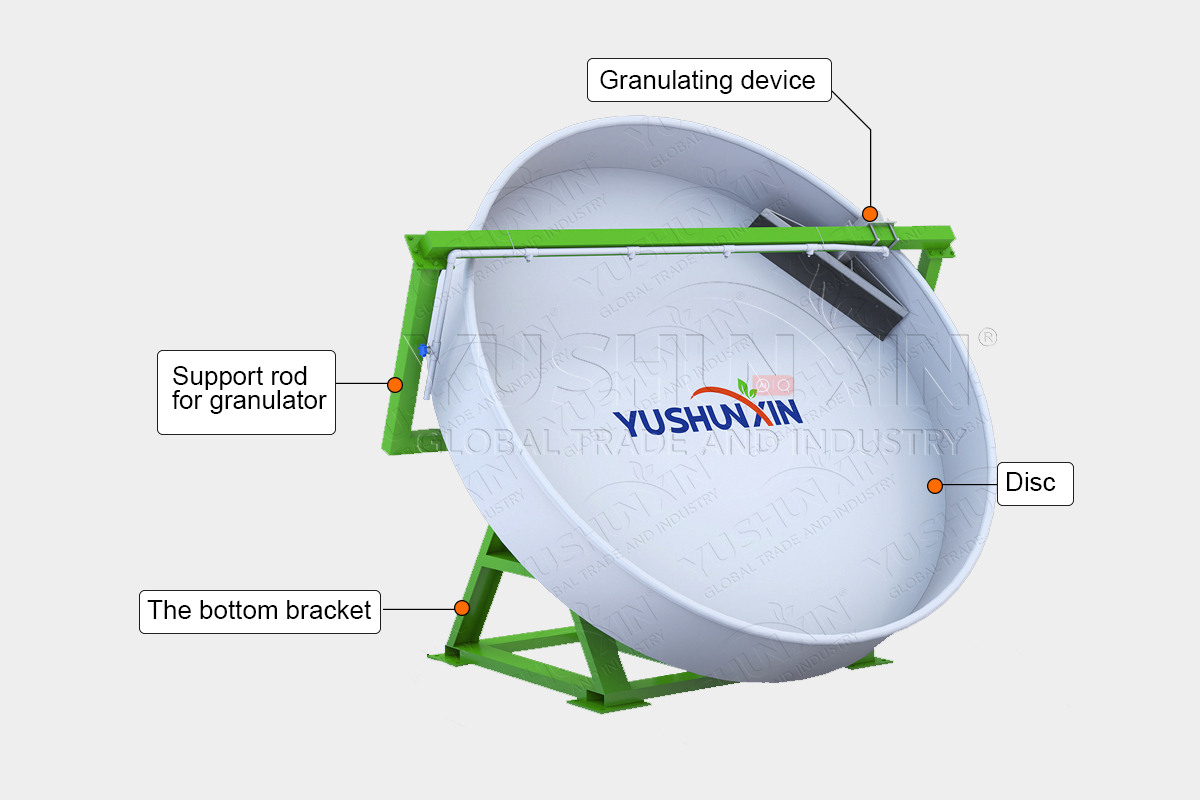

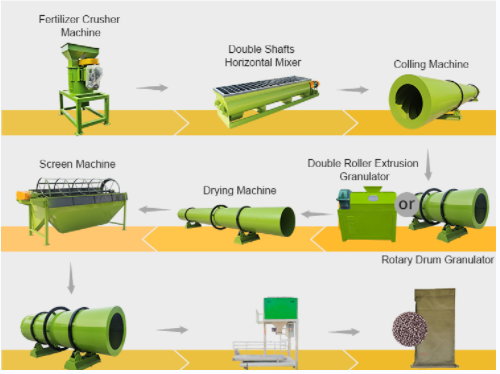

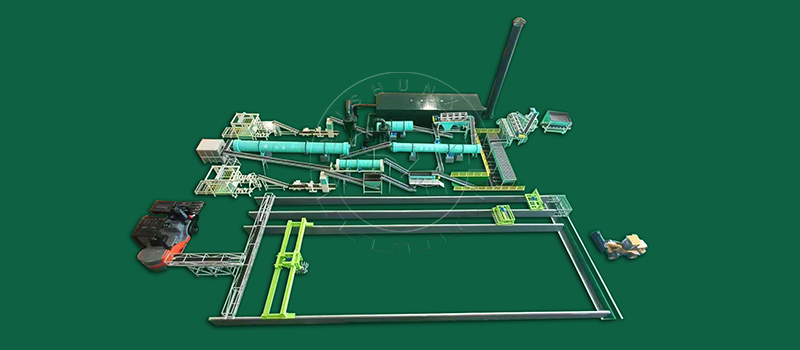

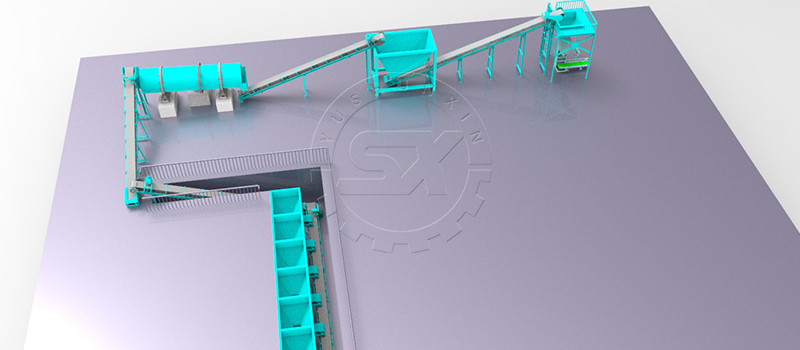

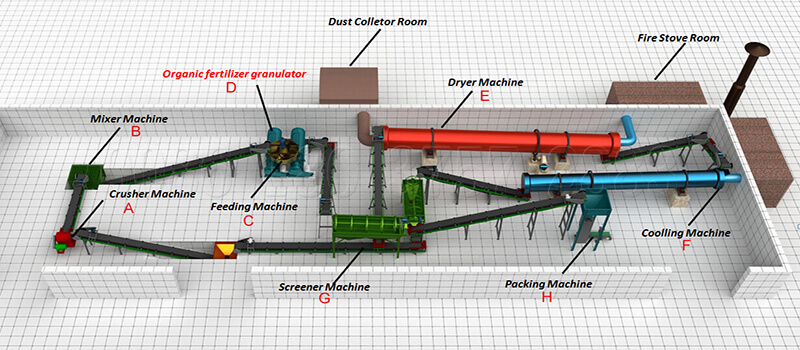

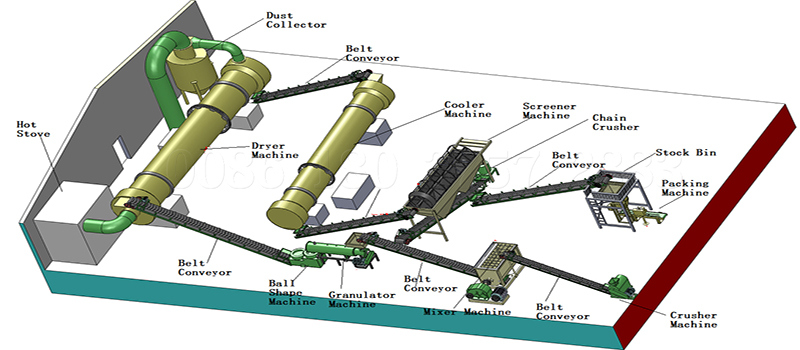

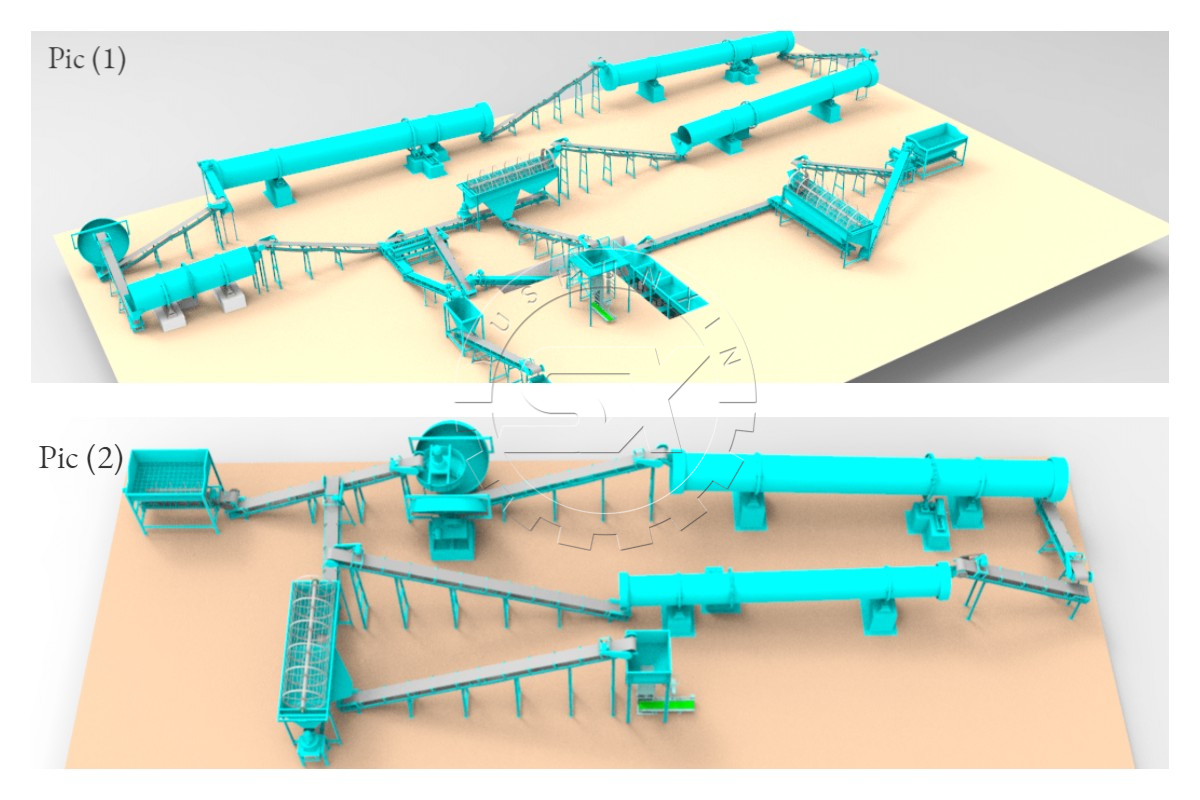

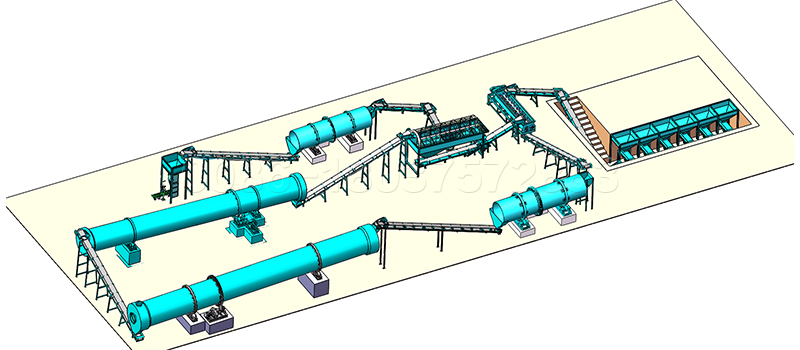

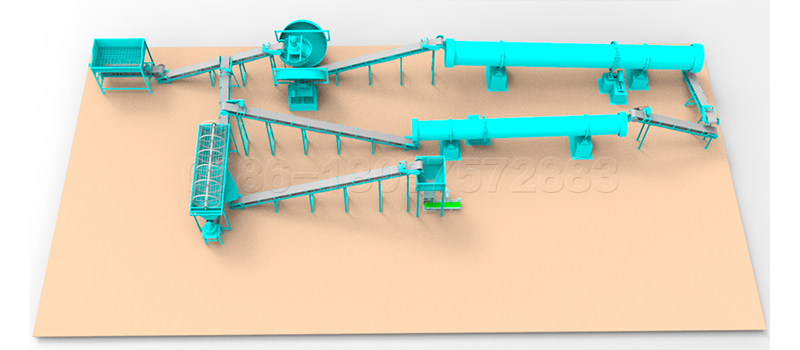

Модульная конструкция: Мы можем предложить индивидуальные решения, включая различные модели (канальные, башенные, барабанные), в зависимости от характеристик вашего сырья (солома, навоз, осадок сточных вод) и потребностей в производительности (от 1 до сотен тонн в сутки).

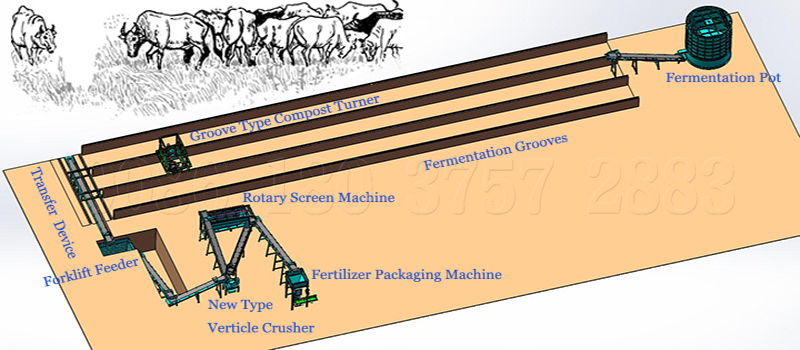

Гусеничные-ворошители-компост

Этот компостер создан для следующих сценариев:

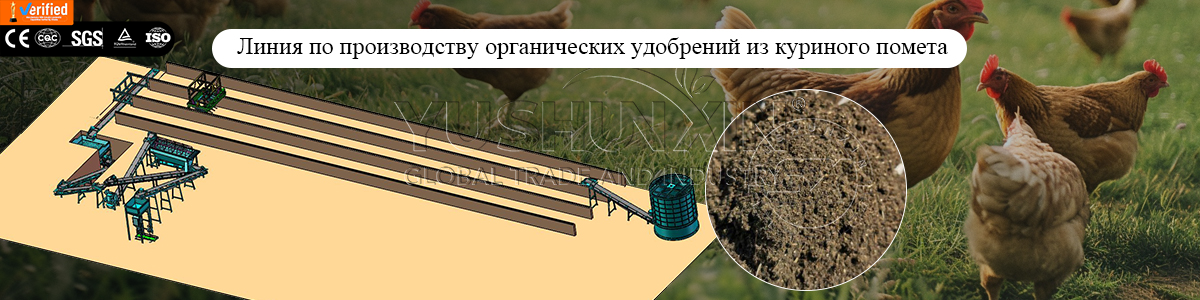

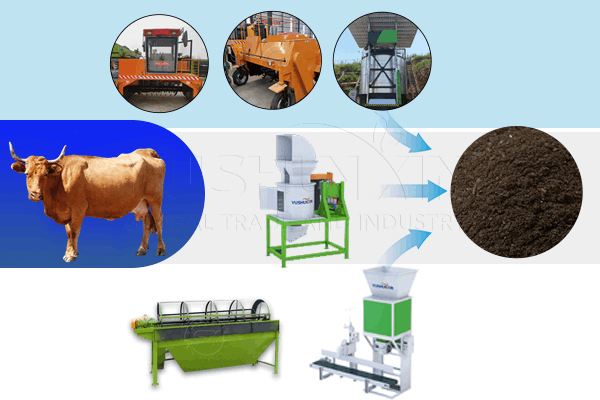

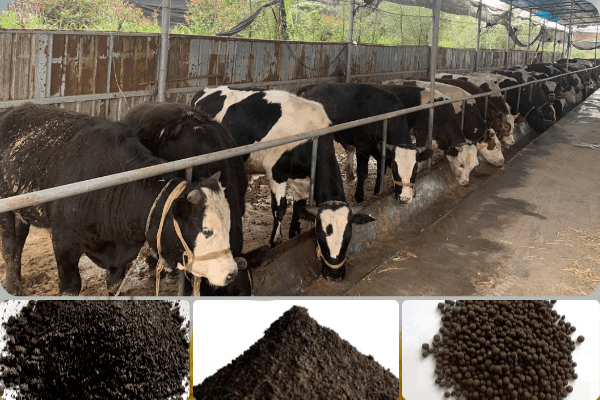

Крупные животноводческие предприятия: Идеально подходит для переработки свиного, птичьего, коровьего навоза, превращая источник загрязнения в источник дохода и одновременно решая экологические проблемы.

Современные агропромышленные парки и фермерские хозяйства: Переработка собственных растительных остатков и отходов для производства удобрения для собственных нужд, снижение затрат и повышение качества продукции.

Коммунальные службы озеленения и ландшафтные компании: Эффективная переработка веток, листвы, зеленых отходов для производства собственного почвоулучшителя.

Заводы по производству органических удобрений и инвесторы: Использование в качестве основного оборудования для закупки и переработки органических отходов с производством товарного органического удобрения на продажу, создание устойчивой бизнес-модели.

Экопарки и экологические проекты: Замыкание цикла переработки органических отходов на территории, реализация принципов углеродной нейтральности.

Выбирая нас, вы получаете гораздо больше, чем просто оборудование:

1. Профессиональное консультирование: Индивидуальный подход к проектированию процесса и выбору оборудования на основе вашего сырья и площадки.

2. Под ключ: Полный комплекс услуг: от подготовки фундамента и монтажа до пусконаладки и обучения персонала.

3. Всесторонняя поддержка: Обеспечение гарантийного и послегарантийного обслуживания по всей стране, оперативная техническая поддержка и наличие запасных частей для бесперебойной работы.

4. Помощь в построении бизнес-модели: Делимся отраслевыми знаниями, помогаем в поиске каналов сбыта готового удобрения для максимизации возврата на инвестиции.

Horizontal fermenter for biofertilizer compost

Действуйте сейчас, чтобы запустить свой цикл «зеленого» богатства!

Инвестиции в эффективный компостер — это не только экологическое решение, но и разумная бизнес-инвестиция. Это означает:

Превращение постоянных затрат на утилизацию в стабильный дополнительный доход.

Превращение экологических проблем в конкурентное преимущество и образ социально ответственной компании.

Насыщение вашей почвы или продукции настоящим источником здоровья и эффективности.

Не позволяйте ценным ресурсам пропадать зря!

Свяжитесь с нами прямо сейчас, чтобы получить:

1. Индивидуальное предложение и расчет стоимости: Отправьте информацию о вашем сырье и потребностях в производительности.

2. Посещение действующих объектов (при возможности): Увидите работу оборудования и образцы готовой продукции своими глазами.

3. Бесплатную техническую консультацию: Наши инженеры ответят на все ваши вопросы о процессе компостирования.

Начните ваше путешествие в мир органического цикличного сельского хозяйства с профессиональной беседы. Для получения более подробной информации, пожалуйста, посетите:https://www.liniyaudobreniy.com/kompost/