Phosphate fertilizers play a crucial role in modern agriculture by supplying essential nutrients that support the growth and development of crops. As the global population rises and the demand for food increases, efficient production of phosphate fertilizers becomes ever more important. In this blog, we’ll explore the key equipment used in the ssp fertilizer making, and how these tools help meet the world’s agricultural needs.

Understanding Phosphate Fertilizers

Phosphate fertilizers contain phosphorus, one of the primary nutrients required for plant growth, alongside nitrogen and potassium. These fertilizers are produced from phosphate rock, a mineral mined in several parts of the world. The phosphorus in phosphate rock is not readily available to plants, so it must first be processed into a more soluble form – Making phosphate rock into solid SSP fertilizer this is where phosphate fertilizer production equipment comes into play.

The Phosphate Fertilizer Production Process

Phosphate fertilizer production process typically involves several key steps, each requiring specialized equipment:

1. Mining and Beneficiation

The first step in phosphate fertilizer production is the mining of phosphate rock. Once extracted, the rock undergoes beneficiation to separate it from unwanted materials and to concentrate the phosphate mineral.

Key Equipment

– Draglines, bucket wheel excavators, or shovels for mining.

– Crushers and grinders for phosphate rock size reduction.

– Flotation cells for separating phosphate from other minerals.

2. Phosphoric Acid Production

Beneficiated phosphate rock is then processed into phosphoric acid, a precursor to many phosphate fertilizers.

Key Equipment:

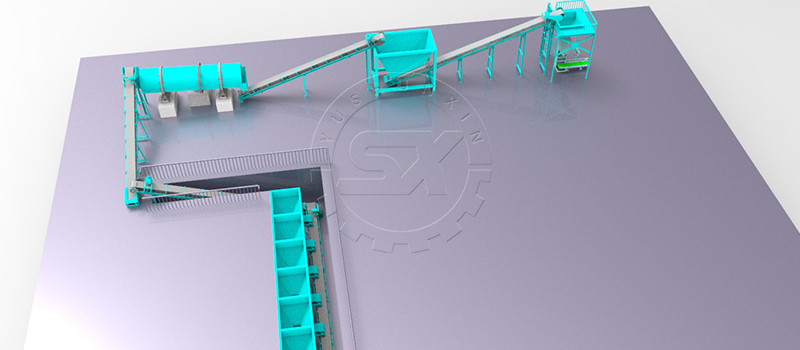

– Batching machine for feeding sulfuric acid and phosphate rock powder in required proportation.

– Reactors or workshop where the reaction between phosphate rock and sulfuric acid takes place.

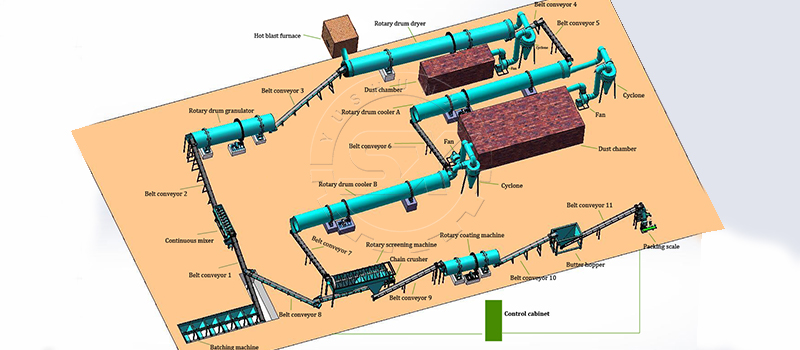

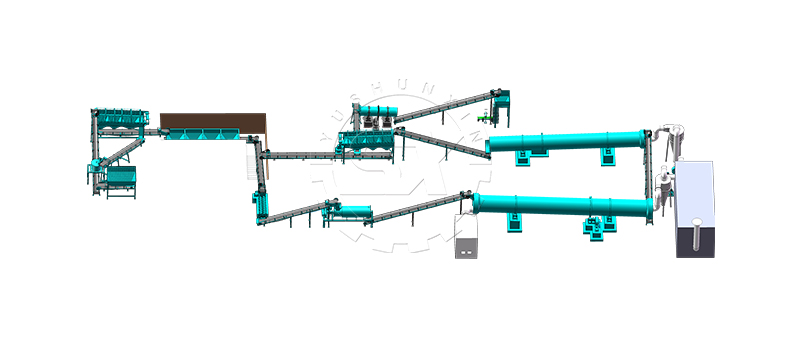

3. Fertilizer Granulation

The phosphoric acid is then mixed with other nutrients like nitrogen and potassium to create different types of phosphate fertilizers. The mixture is granulated to produce a user-friendly product.

Key Equipment:

– Mixers to combine phosphoric acid with other nutrients.

– Granulators, like rotary drum granulators or pan granulators, to prepare SSP granules.

– Dryers to remove moisture from the granules.

– Coolers to reduce the temperature of the granules after drying.

Click here to learn more.

Single super phosphate fertilizer granule making machine with stainless steel lining

4. Quality Control and Packaging

Finally, the granulated fertilizer is tested for quality control to ensure it meets the required standards before being packaged for distribution.

Key Equipment:

– Screens for sorting granules by size.

– Coating drums for applying a protective layer to the granules.

– Packaging machines for bagging the fertilizer.

Advancements in Phosphate Fertilizer Production Equipment

Advancements in technology have led to the development of more efficient and environmentally friendly phosphate fertilizer production equipment. Innovations include improved reactor designs for acid production, enhanced SSP fertilizer manufacturing technologies, and advanced granulation systems that reduce waste and energy consumption. You can visit https://www.manuremanagementplan.com/single-super-phosphate-fertilizer-manufacturing-plant/ to learn more.

Challenges in Phosphate Fertilizer Production

Despite technological progress, several challenges remain in phosphate fertilizer production, including the sustainable sourcing of phosphate rock, the handling of by-products like gypsum, and the need for energy-efficient processes. Manufacturers are also under pressure to reduce emissions and the environmental impact of their operations.

Conclusion

The production of SSP fertilizers is a complex process that requires a variety of specialized equipment. From the extraction of phosphate rock to the granulation of the final product, each step plays a vital role in transforming raw materials into the nutrients that support global food production. As the demand for phosphate fertilizers continues to grow, so too does the need for innovation and sustainability in the equipment and processes used to produce them. With ongoing advancements, the phosphate fertilizer industry is poised to meet these challenges, ensuring that agriculture remains productive and sustainable for years to come.