Large-scale composting systems are designed to efficiently process organic materials on a massive scale, typically for municipalities, commercial operations, or agricultural purposes. These systems help reduce the environmental impact of organic waste by diverting it from landfills and incinerators while creating valuable compost that can be used to enrich soil. Here are key components and considerations for large-scale compost systems:

Input Materials

Large-scale compost systems can handle a wide range of organic materials, including food scraps, yard waste, agricultural residues, and sewage sludge. Proper feedstock management is essential to maintain a balanced carbon-to-nitrogen ratio.

Site Selection

Choosing an appropriate location is crucial. Factors such as accessibility, zoning regulations, proximity to waste sources, and potential odor concerns need to be considered.

Aeration

Effective aeration is vital for large-scale composting. Compost piles or windrows need to be turned regularly to provide oxygen to the microorganisms responsible for decomposition. Commercial compost turning equipment is often used in large systems.

Temperature Control

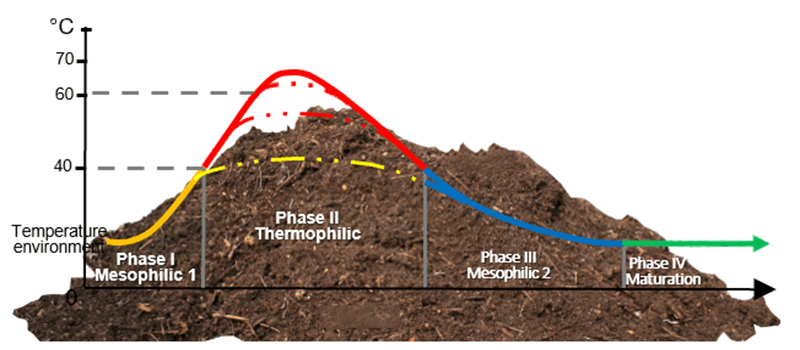

Temperature control is essential in large scale composting process. Proper insulation and monitoring systems are used to ensure that the compost reaches and maintains the necessary temperatures for decomposition (usually between 130°F to 160°F or 54°C to 71°C).

Temperature changing in large organic fertilizer composting

Moisture Management

Maintaining the right moisture content is critical in aerobic fermentation. Compost piles should have a moisture content of around 50-60%. Irrigation or covering with a waterproof membrane can help control moisture.

Size and Configuration

Large-scale compost systems can take various forms, such as windrows, aerated static piles, in-vessel systems, or digesters. The choice depends on the available space, feedstock characteristics, and desired processing capacity. Click here to learn more.

Odor and Pest Control

Odor management is crucial to address community concerns. Aerating the compost, covering it with materials like wood chips, and using odor-neutralizing agents can help. Pest control measures, such as rodent-proofing, are also essential.

Manure compost produced by SX fermenter

Monitoring and Testing

Regular monitoring of temperature, moisture, and oxygen levels is essential for process control. Compost quality should be tested to ensure it meets regulatory standards and is suitable for its intended use.

Regulatory Compliance

Large-scale composting facilities must adhere to local, state, and federal regulations related to waste management, environmental protection, and public health.

End Product Use

The compost produced can be used in various applications, such as agriculture, landscaping, erosion control, and soil remediation. Developing markets for the compost is essential for the economic viability of large-scale composting operations.

Safety

Safety protocols and equipment are critical, especially when using heavy machinery and dealing with potentially hazardous materials.

Community Engagement

Large-scale composting facilities often face public scrutiny. Engaging with the local community through education and addressing concerns can help build support and minimize conflicts.

Large-scale composting systems play a vital role in sustainable waste management, reducing landfill waste, and producing valuable organic matter to improve soil health. However, they require careful planning, management, and investment to operate efficiently and minimize environmental impacts. If you need a more detailed compost plan, you can visit https://fertilizerequipmentmanufacturer.com/large-scale-composting-equipment/