Creating your own organic granular fertilizer is a rewarding and eco-friendly way to enhance the fertility of your garden soil. By utilizing natural ingredients and avoiding synthetic chemicals, you can promote healthy plant growth and contribute to a sustainable gardening practice. In this comprehensive guide, we will walk you through the step-by-step process of making organic granular fertilizer from readily available materials.

Ingredients and Tools: Before you start, gather the following ingredients and tools:

- Kitchen Scraps: Collect kitchen scraps such as fruit and vegetable peels, coffee grounds, and eggshells. These organic materials will serve as the base for your fertilizer, providing essential nutrients like nitrogen, phosphorus, and potassium.

- Bone Meal or Fish Meal: Obtain bone meal or fish meal from a reputable source. These ingredients are rich in phosphorus and protein, supporting root development and overall plant health.

- Wood Ash: Save wood ash from your fireplace or wood-burning stove. Wood ash contains potassium, which is crucial for flowering and fruiting plants.

- Epsom Salt: Purchase Epsom salt, a natural source of magnesium. Magnesium is essential for photosynthesis and helps plants absorb other nutrients more effectively.

- Seaweed or Kelp Meal: Acquire dried seaweed or kelp meal to introduce trace minerals and growth hormones that promote plant resilience and vigor.

- Compost: Use well-rotted compost to enhance the overall organic matter content in your fertilizer mix.

- Mixing Container: Select a large mixing container, such as a wheelbarrow or a plastic bin, to combine and blend the ingredients thoroughly.

- Gardening Gloves: Protect your hands with gardening gloves while handling the materials.

Step-by-Step Process:

Step 1: Collecting Kitchen Scraps

Gather kitchen scraps like fruit and vegetable peels, coffee grounds, and eggshells. Avoid adding meat, dairy, or oily items.

Step 2: Preparing Bone or Fish Meal

Measure the appropriate amount of bone meal or fish meal. These ingredients are rich in phosphorus, essential for strong root development.

Step 3: Incorporating Wood Ash

Add wood ash to the mix, ensuring a balanced source of potassium for flowering and fruiting plants.

Step 4: Introducing Epsom Salt

Include Epsom salt to provide magnesium, a crucial element for photosynthesis and nutrient absorption.

Step 5: Incorporating Seaweed or Kelp Meal

Mix in dried seaweed or kelp meal to introduce trace minerals and growth hormones, enhancing plant resilience.

Step 6: Blending with Compost

Combine the prepared ingredients with well-rotted compost, creating a well-rounded and nutrient-rich fertilizer base.

Step 7: Thorough Mixing

Put on your gardening gloves and thoroughly mix all the ingredients in the container. Ensure an even distribution for a balanced fertilizer.

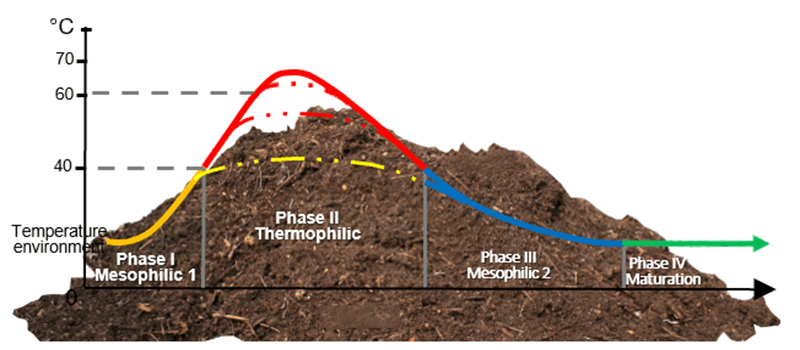

Step 8: Curing the Fertilizer

Allow the fertilizer mix to cure for at least two weeks. This resting period allows the components to integrate and activate beneficial microorganisms.

Step 9: Storage

Once cured, store your homemade organic granular fertilizer in a dry, airtight container. Use it as needed throughout the growing season.

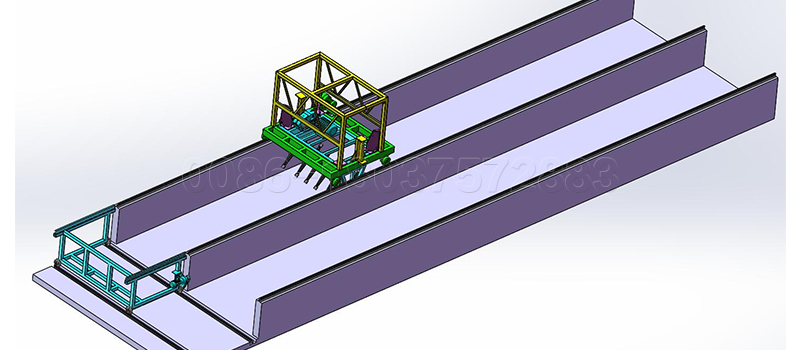

Conclusion: By following these simple steps, you can create a powerful and sustainable organic granular fertilizer for your garden. This DIY approach not only reduces your environmental impact but also fosters a healthier and more vibrant garden, promoting long-term soil fertility and plant vitality. And if you want to setup an organic fertilizer plant, SX can provide you with the best solution.