The complex procedures of mineral fertilizer processing require advanced equipment and accurate granulation technology. Rock, ore, and mineral-based fertilizers often demand special machinery for crushing, mixing, granulating, and screening. Among these technologies, pan granulators, also called disc granulation machines, play a central role in improving efficiency, consistency, and product quality. When manufacturers in the fertilizer industry understand the relationship between raw material characteristics and granulation equipment, they gain better control over production outcomes, cost, and sustainability.

What Raw Mineral Materials Suit Pan Granulation in Fertilizer Production?

Rock phosphate, dolomite, limestone, bentonite clay, and mine wastes represent the major raw materials in mineral fertilizer manufacturing.

- Rock phosphate fertilizer production requires strong preparation because particles must break down under controlled conditions before final granulation. A disc pelletizer shapes these fine powders into uniform granules that improve handling and storage.

- Limestone fertilizer production solutions depend on fine crushing and careful particle size control. Pan granulating machines provide round ball making for better spreading during later blending processes.

- Bentonite and mine waste management benefit when granulators transform dusty residues into spherical particles. This approach reduces waste accumulation and supports environmental compliance in mineral organic fertilizer production lines.

Every raw material type demands specific fertilizer processing machinery. For instance, a jaw rock crusher or an ore fertilizer crusher machine creates the fine powders, while a Raymond mill refines the mineral particles before the pan granulation stage. Once the raw material enters the disc pelletizer, controlled moisture and rotational angles create consistent pellets ready for downstream screening.

Disc Pelletizer for Rock Fertilizer Making

How Do Disc Pelletizers Improve Mineral Fertilizer Manufacturing Results?

Manufacturers operating in the mining and fertilizer industries understand that granule uniformity is decisive. Mineral fertilizers often contain hard ore particles, and uneven size distribution leads to difficult blending in NPK fertilizer production or bulk fertilizer blending plants. A pan granulation machine addresses these issues by offering:

- Adjustable angle design to regulate pellet size in a precise range.

- Strong structural components that handle dense mineral particles like crushed phosphate rock or iron-rich mine residues.

- Efficient moisture spraying systems that enhance adhesion of mineral powders during the ball making process.

Unlike other granulation procedures, pan granulators allow continuous observation during particle forming. Manufacturers can adjust water quantity, powder feed rate, and disk rotation speed to ensure every ore-based fertilizer granule matches the required standards. As a result, mineral fertilizer manufacturing plants reach higher production efficiency, reduced dust, and improved product storage stability.

Why Must Mineral Fertilizer Plants Integrate Multiple Machines in the Granulation Process?

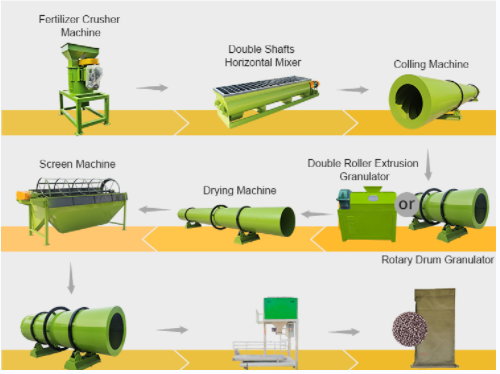

A rock fertilizer production line does not only require disc granulators. Each plant needs a combination of crushing, granulating, and screening equipment to achieve stable results. An ore crusher prepares the mine material by reducing particle size. A disc pelletizer makes uniform granules fit for packaging. A rotary screening machine sorts the final product into qualified mineral pellet sizes, while oversized or undersized material returns to the preparation stage.

This closed-loop system creates consistent quality while reducing waste. For example, in the manufacturing of NPK fertilizer using mined phosphate and potassium ore, the crushing machine provides fine powders, the pan pelletizer granulates them into balanced granules, and the screening machine ensures only accurate particles move toward packaging. In mineral organic fertilizer production lines, the same equipment arrangement guarantees smooth integration of mineral ore powder with organic matter before disc granulation.

How Can Professional Equipment Suppliers Support Long-Term Rock Fertilizer Granulation?

Fertilizer manufacturing plants that rely on mineral ores or mined rocks must continuously upgrade granulation machines to maintain stable yields. The selection of professional equipment suppliers determines whether a plant can handle complex raw materials, optimize production lines, and ensure high utilization of mineral resources. A reliable pan pelletizer ensures long-term performance, but additional support in crushing, screening, and dust control guarantees complete fertilizer production solutions.

A professional fertilizer equipment manufacturer—Yushunxin—provides advanced disc granulators, ore fertilizer crusher machines, and screening equipment suitable for rock phosphate fertilizer production, limestone fertilizer processing solutions, and mineral organic fertilizer plants. With strong technical expertise in granule making and comprehensive mineral resource utilization, Yushunxin delivers machinery that supports efficient production, environmental compliance, and competitive market performance.

Conclusion

The application of pan granulating machines transforms mineral fertilizer procedures by improving granule quality, reducing dust, and enhancing efficiency. Rock, mineral, and ore-based raw materials require careful preparation, and only a complete line of crushers, disc granulators, and screening equipment can ensure consistent results. Manufacturers in the mineral fertilizer industry achieve stronger competitiveness when they adopt reliable machinery from professional suppliers and apply modern pelletizing solutions to challenging raw materials. You can visit: https://www.mineralfertilizerproductionsolutions.com/product/disc-granulator-machine/